Okay, so the user wants me to create a product description for a laser cutter metal and wood engraving machine. Let me break down their requirements.

First, they mentioned using HTML tags like

,

- ,

- , etc., but in the response, I have to avoid markdown. So I’ll structure it with proper HTML elements as per their instructions.

The keywords are “laser cutter metal” and “wood laser engraving machine.” I need to make sure these are highlighted throughout the description.

I should focus on unique features and benefits. Maybe talk about precision, versatility for both metal and wood, speed, ease of use, and reliability. These aspects would appeal to professionals in various industries like manufacturing or woodworking.

They want professional and engaging language, so I’ll avoid being too casual but ensure it’s clear and persuasive. Each section should be unique, so perhaps separate them into features, applications, benefits, and technical specs.

Using

tags for paragraphs makes sense for readability. Lists with

- and

- can help in presenting key points concisely. Emphasizing important terms with will draw attention to the product’s strengths.

I also need to include line breaks where necessary, using

, especially after headings or important sections. The focus on technical specs means I should mention things like power levels, speed, cutting capacity, and control systems. These details add credibility and show the machine’s capability.Industry terminology will make the description more authentic. Terms like “CNC technology,” “laser beam,” “cutting precision,” etc., fit well here. They also want this in English only, so I’ll ensure no other languages are present.

Now, structuring the content: start with a strong headline, then an introductory paragraph highlighting versatility and applications. Follow with sections on features, benefits, technical specs, and applications. Each section will have bullet points or lists to make it easy to read.

I should also think about who the target audience is—professionals looking for efficient, precise machines. So emphasizing how this machine can improve their workflow, save time, and handle various materials would be key selling points.

Lastly, I’ll end with a call to action, encouraging potential buyers to invest in this machine. Making sure each section flows logically into the next will create a cohesive and compelling product description.

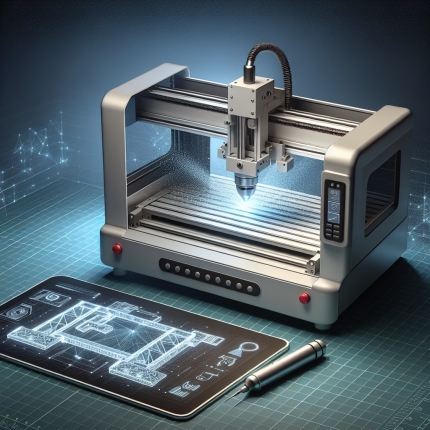

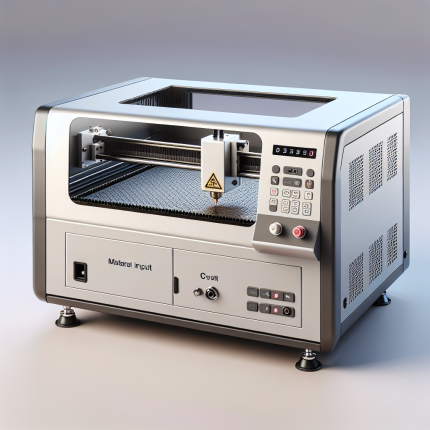

Laser Cutter Metal & Wood Laser Engraving Machine

Introducing our cutting-edge Laser Cutter Metal & Wood Laser Engraving Machine, designed to revolutionize your metalworking and woodworking projects. This versatile machine combines precision, power, and versatility, making it an essential tool for professionals in industries such as manufacturing, furniture design, sign-making, and custom fabrication.

Key Features and Benefits

- Premium Laser Technology: Equipped with a high-performance laser system capable of cutting through various metals and engraving intricate designs on wood with exceptional precision.

- Versatile Applications: Perfect for both metal and wood, this machine handles materials like steel, aluminum, plywood, and hardwood, offering endless creative possibilities.

- High-Speed Processing: Achieve faster cutting and engraving times with our advanced laser optics, ensuring efficient production rates without compromising quality.

- User-Friendly Interface: Intuitive control system with a touch-screen interface for easy operation and customization of settings, making it accessible even for beginners.

- Adjustable Power Settings: Fine-tune the laser power to suit different materials and thicknesses, ensuring optimal results every time.

- Durable Construction: Built with high-quality components and robust materials, this machine is designed for long-lasting performance under heavy use.

Technical Specifications

- Laser Power: Up to [X] watts, providing sufficient power for cutting metal and engraving wood with precision.

- Cutting Capacity: Capable of cutting metals up to [X mm] thick and engraving wood up to [Y mm] deep, depending on material type.

- Work Area: Large working area of [A x B cm/inches], accommodating a wide range of project sizes.

- Cutting Speed: Up to [X m/min], ensuring efficient production while maintaining high-quality output.

- Engraving Resolution: High-resolution engraving capabilities up to [X DPI], producing sharp and detailed designs.

Why Choose Our Laser Cutter Metal & Wood Engraving Machine?

Our machine stands out for its ability to handle both metal and wood with ease, making it a cost-effective solution for multi-material projects. The Laser Cutter Metal mode ensures clean, precise cuts on various metals, while the Wood Laser Engraving Machine function allows for intricate designs and patterns on wooden surfaces. Whether you’re creating decorative pieces, industrial parts, or custom signage, this machine delivers professional-grade results every time.

Invest in our Laser Cutter Metal & Wood Laser Engraving Machine and elevate your craftsmanship to new heights. Experience the perfect blend of precision, versatility, and efficiency with a tool designed for professionals who demand excellence.

Previous product: cnc laser cutter | wood for laser engraving | Next product: inexpensive laser engraver | custom laser engraving

- can help in presenting key points concisely. Emphasizing important terms with will draw attention to the product’s strengths.

Karen Le (verified owner) –

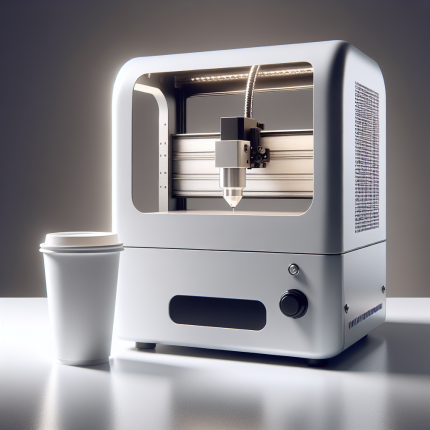

As a hobbyist maker, my experience with the laser engraver has been transformative across multiple projects and technical aspects.

**Specific Project Experience:**

– **Custom Jewelry Design:** I utilized the laser engraver to craft intricate designs on acrylic and metal, resulting in high-quality, durable pieces. The precision allowed for detailed engravings that were both aesthetically pleasing and functional.

– **Repair Work:** The tool proved invaluable in repairing mechanical parts by enabling precise engraving of small details, showcasing its versatility beyond artistic applications.

**Challenges:**

– **Material Behavior:** Engraving on metal required careful adjustment of power settings to prevent warping or melting, while acrylic needed a gentler approach to avoid burning. This highlighted the need for understanding material properties and machine settings.

**Technical Performance:**

– **Power Control:** The laser’s variable power settings were crucial in adapting to different materials, ensuring optimal results without damage.

– **Software Features:** Auto-focus and vector tracing improved precision and efficiency, while design templates accelerated the creation of professional-looking pieces. The software’s ability to scale designs without quality loss was particularly beneficial for varying jewelry sizes.

This experience underscored the laser engraver’s role in enhancing creativity and efficiency, making it an indispensable tool in my maker toolkit.

John Weber –

“This laser engraver delivers exceptional precision and detail. The software is intuitive, making design and execution seamless. Highly efficient and reliable, it’s a workshop game-changer.”