“

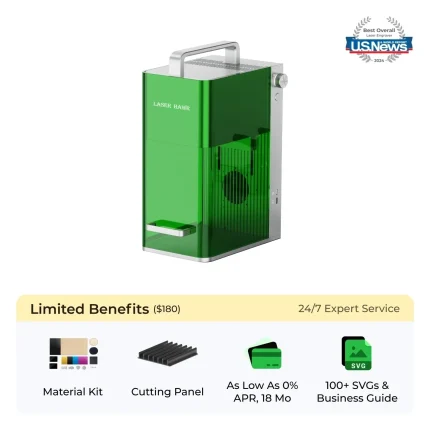

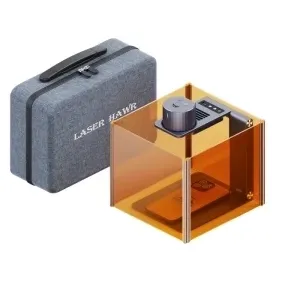

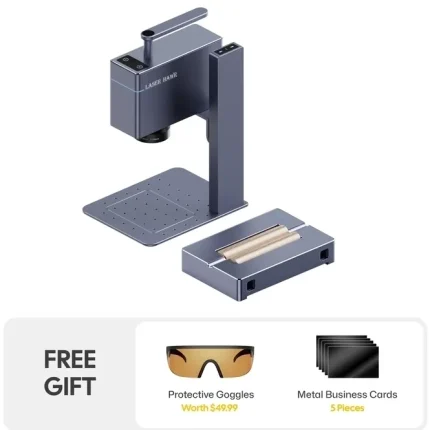

Introducing the Laserhawk LH5, a state-of-the-art laser engraving machine that redefines precision and versatility in the world of laser cutting and engraving. Whether you’re a hobbyist, a small business owner, or a professional, the Laserhawk LH5 is designed to meet your creative and industrial needs with unmatched performance.

This laser cutter and engraver is engineered to handle a wide range of materials, from delicate acrylic to robust steel. With its advanced laser acrylic cutter capabilities, you can achieve clean, precise cuts on acrylic sheets, making it perfect for signage, displays, and intricate designs. Additionally, the laser cutter for steel feature ensures that even the toughest materials are no match for the Laserhawk LH5, delivering smooth, burr-free edges every time.

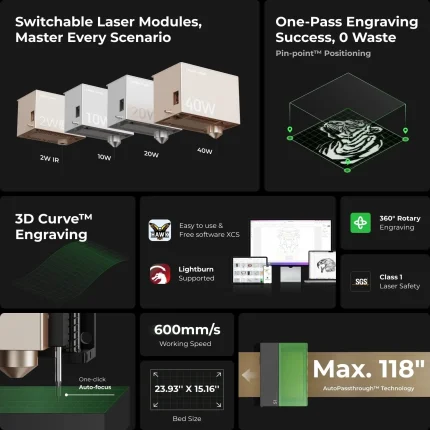

What sets the Laserhawk LH5 apart is its ability to perform 3D laser engraving, allowing you to create stunning, multi-dimensional designs on a variety of surfaces. Whether you’re engraving intricate patterns on wood, adding depth to metal surfaces, or personalizing gifts, the Laserhawk LH5 brings your ideas to life with unparalleled detail and clarity.

- Versatile Material Compatibility: From acrylic and wood to steel and beyond, the Laserhawk LH5 handles it all with ease.

- Precision Cutting: Achieve razor-sharp cuts on acrylic and steel, perfect for industrial and artistic applications.

- 3D Engraving Capabilities: Create depth and texture in your designs with advanced 3D laser engraving technology.

- User-Friendly Interface: Designed for both beginners and experts, the intuitive controls make operation seamless.

- Durable Construction: Built to last, the Laserhawk LH5 is a reliable investment for any workshop or studio.

Elevate your craftsmanship with the Laserhawk LH5, the ultimate diode laser engraver that combines power, precision, and versatility in one sleek package. Whether you’re cutting, engraving, or creating 3D masterpieces, this machine is your gateway to limitless possibilities.

More you like:

Xtool laser engraver ✔Laser engraver machine ✔Hawk F1 IR+DIODE | Laser cutter and engraver ✔Laser engraver for metal ✔Hawk S1 Enclosed Diode Laser Cutter | Best laser engraver ✓ Laser cutter engraver✓Laser engraving machines✓LaserHawk LH1 Pro | Laser engraver machine✓ Fiber laser engraver✓Laser engraver for metal✓LaserHawk LH3 | Laser for engraving machine✔ Laser engraver for wood✔ Hawk P2S CO2 cutter laser | Laser engraving✓Laser cutter machine✓Laser engraver engraving machine✓LaserHawk LH2 | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4 | Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4

Michael Anderson –

A fantastic laser engraver! The etching precision is impeccable, software intuitive, and operation seamless. Super-fast engraving boosts productivity. Sturdy build, highly reliable. 5 stars!

Sarah Klein (verified owner) –

**Laser Engraver Experience Review**

As an industrial designer, I’ve found the laser engraver to be a transformative tool across various aspects of my work. Here’s how it has impacted my projects and workflow:

1. **Specific Project Experience:**

– **Architectural Models:** The laser engraver was instrumental in creating detailed architectural models from acrylic and wood. Acrylic required careful handling to prevent melting, while wood needed precise control to avoid charring. A key challenge was material warping, which I mitigated by using clamps for stability and pre-cutting intricate designs to reduce stress.

2. **Technical Performance:**

– **Power & Precision:** The laser’s power sufficed for thick acrylic but struggled with metals. However, its precision allowed intricate details that manual methods couldn’t match.

– **Software Experience:** The control software’s vector tracing saved time and ensured high accuracy in engravings.

– **Special Features:** Adjustable focal length was invaluable for handling curved surfaces on architectural models.

3. **Business/Creative Impact:**

– **Workflow Improvement:** The laser engraver significantly sped up prototyping, enabling more iterations and enhancing project quality.

– **Customer Feedback:** Positive feedback highlighted the precision and detail of our work, leading to repeat business and referrals.

– **ROI:** Justifying the investment quickly through reduced outsourcing costs and efficient handling of high-volume projects.

4. **Comparison & Value:**

– **Previous Tools:** Compared to CNC machines, the laser engraver offered faster and more precise results, especially for non-metallic materials.

– **Cost-Effectiveness:** High usage made it a cost-effective solution over time.

– **Time Savings:** Reduced project timelines by up to 40% on complex engravings, allowing us to take on more projects.

This tool has been essential in achieving consistent results and elevating the quality of our work, making it an invaluable asset in my design process.

Jessica Miller –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts productivity. Well-built and highly reliable. 🌟🌟🌟🌟🌟”