The Ultimate Guide to Metal Engraving Laser Machines

Metal engraving has long been a craft that combines precision, creativity, and skill. Traditionally, it involved manually carving intricate designs onto metal surfaces using specialized tools. However, with the advent of modern technology, metal engraving laser machines have revolutionized this process, making it faster, more accurate, and accessible to both professionals and hobbyists alike. In this comprehensive guide, we will explore everything you need to know about metal engraving laser machines, their uses, benefits, and how they can transform your projects.

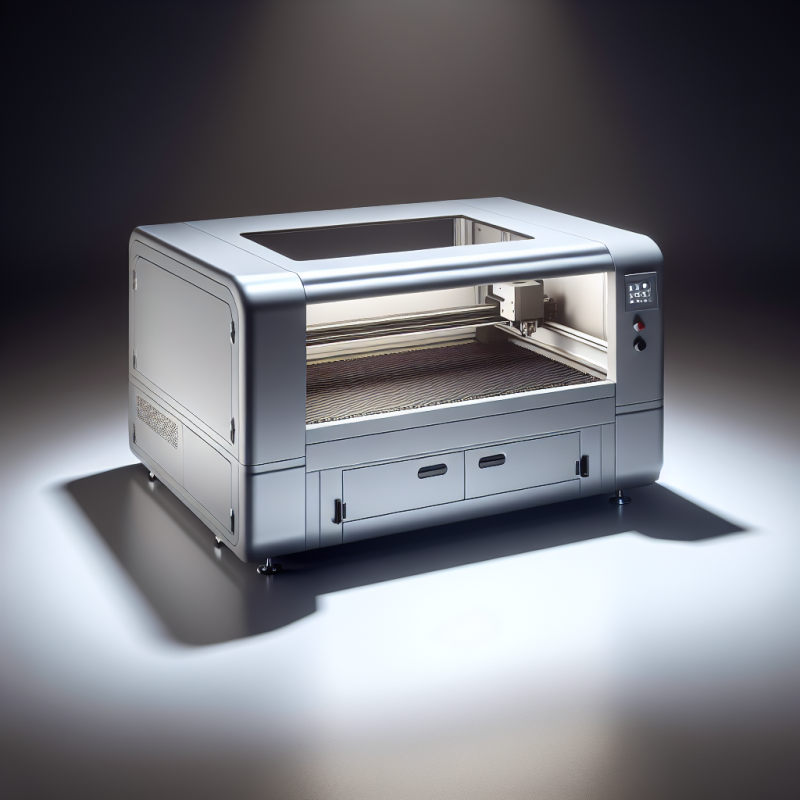

What is a Metal Engraving Laser Machine?

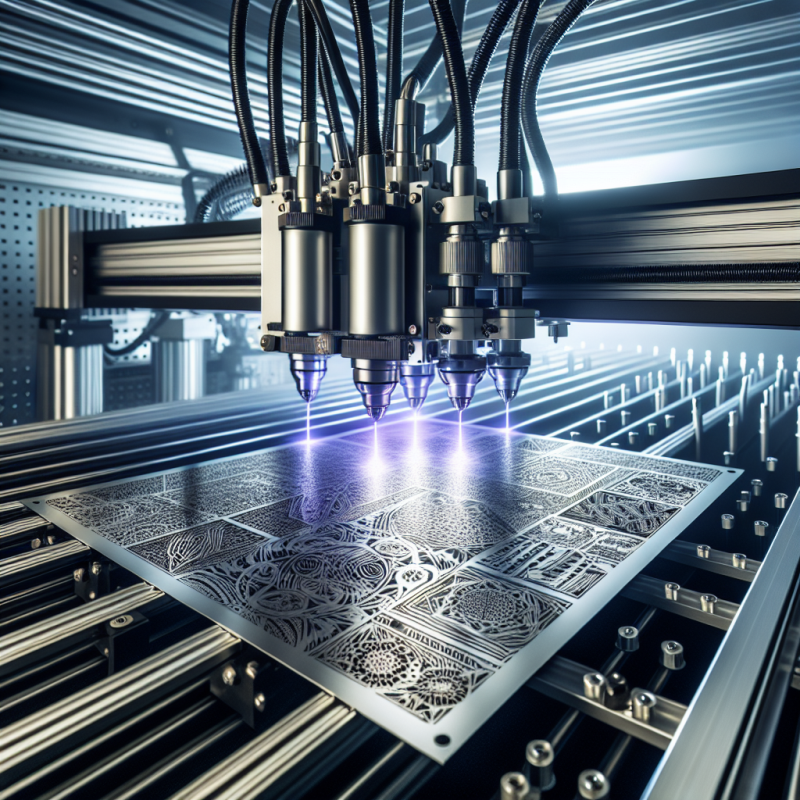

A metal engraving laser machine is a precision tool that uses a high-powered laser beam to cut, etch, or engrave intricate designs onto various materials, including metals. Unlike traditional methods, which often require physical contact and can be time-consuming, laser engraving offers unparalleled speed, accuracy, and versatility. These machines are widely used in industries such as jewelry making, automotive detailing, custom firearms, and even artistic expression.

The process involves directing a focused laser beam at the metal surface, where it vaporizes or melts the material to create detailed patterns or text. The machine is controlled by software that allows users to input designs, logos, or custom artwork, ensuring unparalleled precision. Whether you’re creating a small badge or a large decorative piece, these machines can handle a wide range of projects with ease.

Types of Metal Engraving Laser Machines

There are several types of metal engraving laser machines available on the market, each designed for specific applications. The most common types include:

- Cutters and Etchers: These machines combine cutting and etching capabilities, making them ideal for creating detailed designs and precise cuts.

- CO2 Lasers: Known for their versatility, CO2 lasers are commonly used for engraving metals, wood, plastic, and other materials.

- Fiber Lasers: These are high-power machines designed for cutting thicker metal sheets with exceptional accuracy.

- Pulsed Laser Engravers: Ideal for creating fine details, these machines use short laser pulses to etch surfaces without causing excessive heat damage.

If you’re looking for a reliable option, the metal engraving laser machine available at [HawkLaser](https://hawklaser.vip/product/best-laser-engravers-for-home-co2-laser-cutter/) is a great choice. It’s designed for home use but offers professional-grade performance, making it perfect for both small-scale projects and larger production runs.

Key Features of Metal Engraving Laser Machines

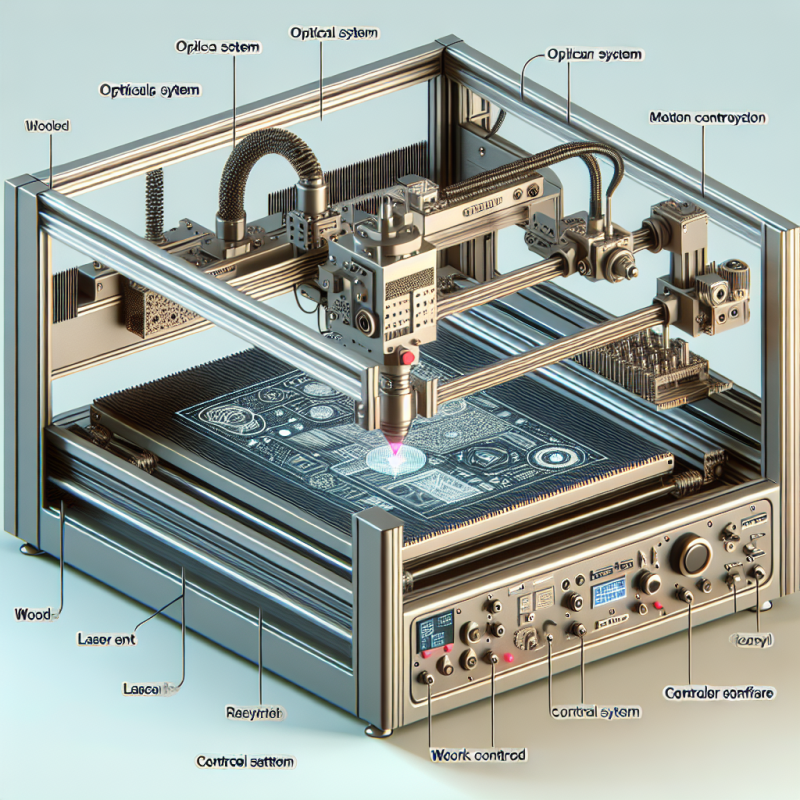

When choosing a metal engraving laser machine, there are several features to consider:

- Laser Power: Higher power lasers are better suited for thicker materials and deeper engravings.

- Focusability: A highly focused beam ensures precise cuts and engravings, reducing the risk of damage to surrounding areas.

- Software Compatibility: Look for machines that are compatible with popular design software like CorelDRAW or Adobe Illustrator.

- Work Area Size: The size of the work area determines how large a project you can undertake. Choose based on your specific needs.

- Automation Capabilities: Some machines offer automation features, such as automatic focusing or material detection, which can save time and improve accuracy.

At [HawkLaser](https://hawklaser.vip/product/best-laser-engravers-for-home-co2-laser-cutter/), their metal engraving laser machine boasts a large work area, high laser power, and user-friendly software, making it an excellent choice for both beginners and experienced users.

Benefits of Using Metal Engraving Laser Machines

The advantages of using a metal engraving laser machine are numerous:

- Precision and Accuracy: Lasers can create incredibly fine details, ensuring that every design is reproduced with precision.

- Speed: Compared to traditional methods, laser engraving is much faster, allowing for quick turnaround times on projects.

- Versatility: These machines can work with a wide range of materials, including stainless steel, aluminum, titanium, and more.

- Reduced Material Waste: Since the laser only affects the area being engraved or cut, there is minimal waste compared to other methods.

- Low Maintenance: Laser machines require less maintenance than traditional engraving tools, reducing downtime and costs.

For those looking to start their journey in metal engraving, the metal engraving laser machine from [HawkLaser](https://hawklaser.vip/product/best-laser-engravers-for-home-co2-laser-cutter/) is an excellent investment. It combines all these benefits into one compact and user-friendly package.

Applications of Metal Engraving Laser Machines

The applications of metal engraving laser machines are almost limitless. Some common uses include:

- Jewelry Making: Creating custom engravings on rings, necklaces, and other jewelry pieces.

- Automotive Industry: Engraving parts numbers, logos, or decorative patterns on car components.

- Firearms Customization: Adding personalized engravings to gun barrels, triggers, and other parts.

- Artistic Expression: Crafting unique metal art pieces with intricate designs.

- Signage Production: Engraving custom signs for businesses or homes.

Regardless of your project size, a metal engraving laser machine can help you achieve professional-quality results. Visit [HawkLaser](https://hawklaser.vip/product/best-laser-engravers-for-home-co2-laser-cutter/) to explore their range and find the perfect machine for your needs.

Maintenance and Safety Tips

While metal engraving laser machines are durable and low-maintenance, proper care is essential to ensure optimal performance. Here are some tips:

- Clean the Machine Regularly: Dust and debris can accumulate inside the machine, so clean it regularly to maintain efficiency.

- Protect Against Moisture: Laser machines are sensitive to moisture, so store them in a dry environment when not in use.

- Follow Safety Guidelines: Always wear protective eyewear and ensure the machine is properly ventilated to avoid inhaling fumes from the engraving process.

- Update Software Regularly: Keep your machine’s software up to date to take advantage of new features and improvements.

By following these tips, you can extend the life of your metal engraving laser machine and ensure it continues to perform at its best. For more information on maintaining your machine, visit [HawkLaser](https://hawklaser.vip/product/best-laser-engravers-for-home-co2-laser-cutter/).

Frequently Asked Questions

Q: Can I use a metal engraving laser machine for other materials besides metal?

Absolutely! While these machines are designed primarily for metals, they can also work with wood, plastic, and other materials. This makes them highly versatile for various projects.

Q: Is it difficult to learn how to use a metal engraving laser machine?

No, most modern machines come with user-friendly software and intuitive controls. With some practice, even beginners can create stunning designs.

Q: How much does a metal engraving laser machine cost?

The cost varies depending on the model and features. At [HawkLaser](https://hawklaser.vip/product/best-laser-engravers-for-home-co2-laser-cutter/), you can find affordable yet high-quality options that suit any budget.

Conclusion

If you’re looking to enter the world of metal engraving or enhance your current setup, a metal engraving laser machine is an invaluable tool. Offering precision, speed, and versatility, these machines can elevate your projects to new heights. Visit [HawkLaser](https://hawklaser.vip/product/best-laser-engravers-for-home-co2-laser-cutter/) today to explore their selection and find the perfect machine for your needs. Start creating stunning metal engravings with ease and confidence!